Blog

WELCOME TO OUR BLOG

WELCOME TO OUR BLOG

"The Leading-edge in training"

"The Leading-edge in training"

Here we connect with you, we discuss topics that concern and affect the off shore world even more precisely the wind energy sector. Please connect and comment on our posts

Challenge

Challenge

Every successful product is the fruit of hard work, and this applies to everything. We have faced lots of challenges in developing our course and business and we do intend to share some of them on this blog

Value

We understand how busy it can be and how important your time is as a technician. so we are only committed to provide you with whats valuable

OUR POSTS

OUR POSTS

By Emmanuel Lewu

•

07 Dec, 2021

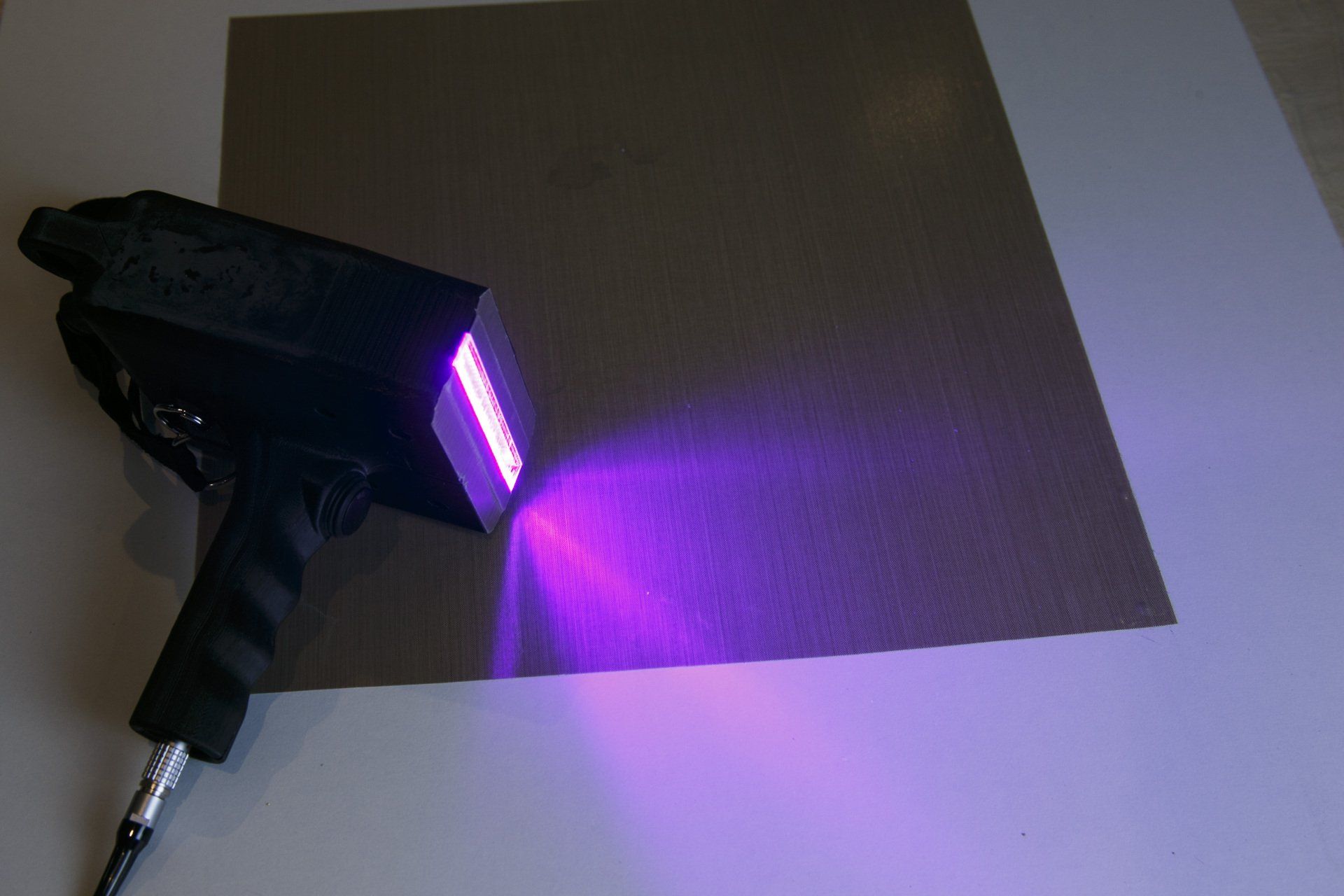

For a while, a lot of development and research has been done in getting more creative and quicker means of performing blade repairs. As wind farms age and new turbines grow in height and blade size, the demand for maintenance and repair services is increasing at a rapid rate. Because of this, many new companies have emerged in recent years to meet the demands of wind farm owners and OEM’s looking for composite blade repairs. Many accidents occur as well as time spent on these repairs are elongated, inefficient and they sometime cause longer lasting recurring problems. Treatment options for damaged blades often vary depending on the blade’s brand, geographic location, and ultimate repair needs. Blade erosion is a common side effect of the harsh weather conditions most turbines face over time. Repairs for erosion are considered cosmetic and are often completed externally on the blade. Gurit, has been on the forefront of development and innovation of creative means of repairs, materials and work tools for blade repair that have been effective as well as cut down spent time and accidents on repairs.

© 2024. The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.